We would like to take this opportunity to wish everyone a Happy Christmas and a Healthy and Prosperous 2024 from all the Team at OSIL. Our office will close for Christmas from Friday 22nd December and reopen on Wednesday 3rd January 2024.

Read MoreNews

Christmas 2022

We would like to take this opportunity to wish everyone a Happy Christmas and a Healthy and Prosperous 2023 from all the Team at OSIL.

Read MoreEaster Bank Holiday

Our offices will be closed on Friday 15th and Monday 18th April 2022 for the Easter Holidays. We will reopen at 9am on Tuesday 19th April. Enjoy the long weekend and Happy Easter.

Read More

Christmas

Wishing you all a Merry Christmas & a Happy New Year. We will close for Christmas on Friday 24th December and reopen on 4th January, 2022.

Read More

Top 5 Reasons for Odour Control System Failures

Today’s odour control systems are engineered intricately to maximise removal rates from high air flows with efficient, compact designs. System failures are primarily caused by engineering and design issues and odour control systems’ incorrect sizing and specification. This article will explore the top five reasons for odour control system failures. Specifying solutions based on guesswork […]

Read More

How To Estimate the Odour Control Unit Capacity?

Whether we’re talking about chemical storage tanks, lagoons of slurry or food manufacturing, we design every odour control system to achieve a measured removal rate in ouE/m3. Additionally, every odour control system has a flow rate measured in m3/hr, which lets us calculate the system’s treatment capacity. This article will explore these odour control measurements […]

Read More

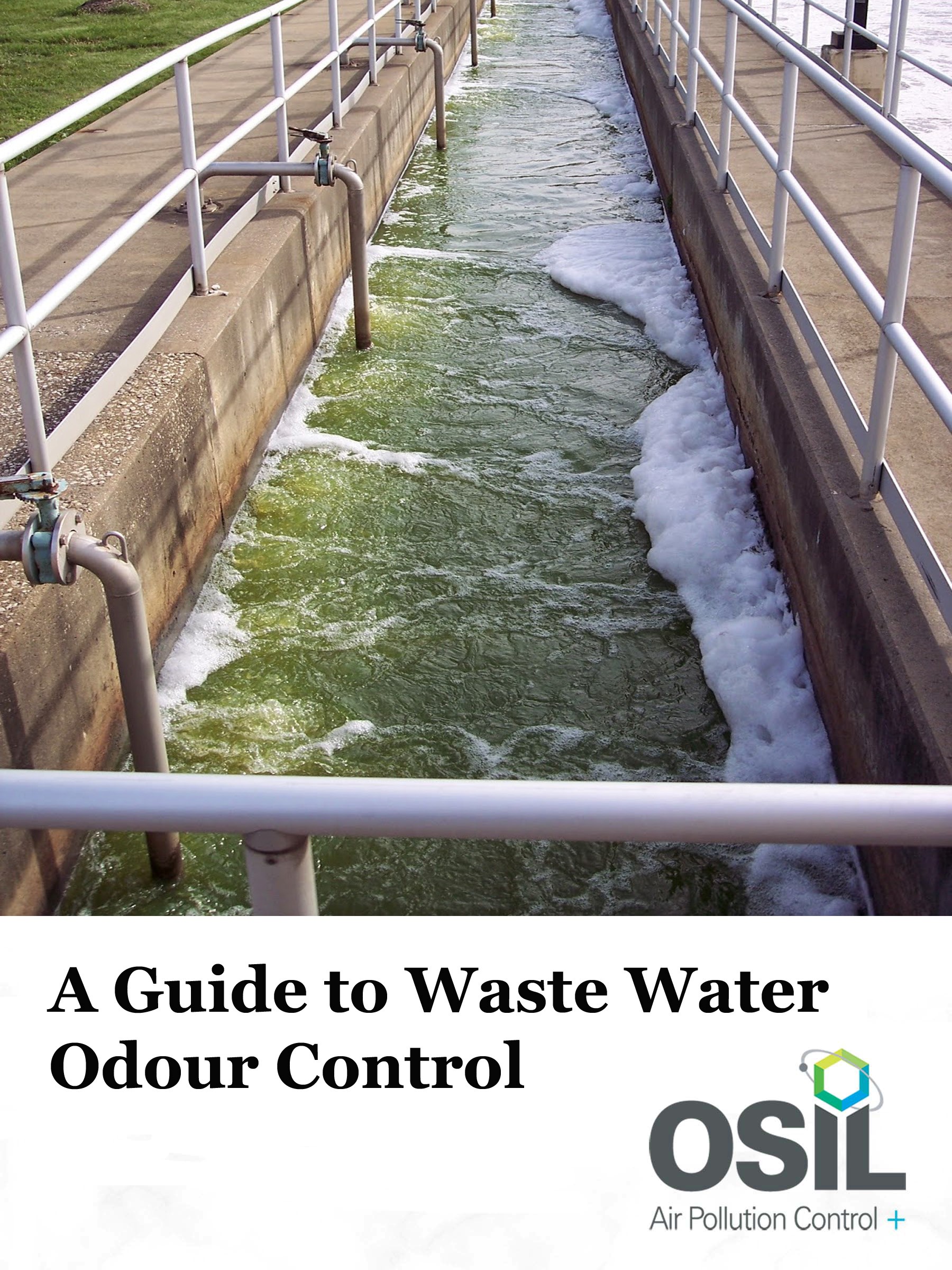

A Guide to Wastewater Odour Control

Find out everything you need to know about waste water odour control. Download your guide to wastewater odour control

Read More

Wastewater Treatment: Are your odour controls optimal?

Wastewater treatment plants are treating more wastewater than ever, and processing volumes are growing each year. As processing volumes grow, treatment works get upgraded or extended, and odour controls should follow suit. However, it is common for a gap to form between wastewater treatment and odour control, creating inefficiencies in the odour removal process. If your odour control process is not […]

Read More

How To Choose the Right Odour Control Technology?

To choose the right odour control technology, first, we need to identify the types of odour you produce and the concentration of the odours. Many processes produce predictable odorous compounds as by-products, like hydrogen sulphide and ammonia. However, we still need to figure out the makeup of the compounds to choose the right odour control […]

Read More

How Odour Control Depends on Service and Maintenance

Odour control systems require regular service and maintenance to prevent equipment failures and assure system performance. Service and maintenance are crucial parts of an odour control system’s life cycle because they manage wear and maximise lifespan. It’s important to note that all odour control systems, biological or chemical, have specific needs that can only be […]

Read More

Industrial Air Pollution Control and DGC Technology Guide

Find out everything you need to know about industrial air pollution control and how OSIL’s DGC technology provides a solution for CO2 removal. Download your guide to Carbon Capture and DGC.

Read More

Get rid of odours at petrol and fuel refineries

Petrol and fuel refineries produce a variety of odorous compounds including sulphides, mercaptans and hydrocarbon compounds. These refinery odours can seep into the atmosphere and cause nuisance complaints, damaging the refinery’s reputation. Inevitably, completely getting rid of petrol and fuel refinery odours isn’t possible – like all odours, we can only control and manage them. […]

Read More

Odour management guidance for refineries

Refineries have their work cut out to control odours and reduce noxious, unpleasant emissions, but with good strategy and advice from experts, it’s possible to abate odours while minimising waste and energy usage. The following odour management guidance for refineries provides an introduction to odour management. For personalised advice, please contact us. Legislation In the […]

Read More

Refinery Odour Control – Key Systems and Technologies

Odour control is an ongoing requirement for industrial oil refineries. Unavoidably, oil refineries produce strong nuisance odours from handling, storing and processing oils, as well as manufacturing fuels, greases and lubricants. Refining crude oil down into its various components releases sulphides, mercaptans and hydrocarbon compounds. Oil refineries also have to contend with odours from combustion, […]

Read More

A guide to Carbon Capture and Downflow Gas Contractor

Find out everything you need to know about Carbon Capture. Carbon capture and storage (CCS) is the process of capturing and storing carbon dioxide (CO2) before it is released into the atmosphere. The DGC technology can capture >99% of CO2. Download your guide to Carbon Capture and DGC.

Read More

Odour Impact Assessment – what’s involved?

An odour impact assessment is a survey assessment that provides a qualitative analysis of the impacts of odours within a local vicinity. Odour impact assessments are a critical part of odour control policy because they provide unique information on the impact of industrial and commercial activities, enabling operators to take action by resolving identified […]

Read More

Everything You Need to Know About Odour Control System Performance Testing

Odour control system performance testing involves physical and automated tests of odour control systems to find problems and assure performance. Performance tests are conducted following the installation, upgrade and repair of odour control systems to certify performance, design and capabilities. Periodic tests can also be performed to track system degradation. The importance of performance […]

Read More

Solutions and Technologies for Odour Management in Organic Waste Facilities

With organic waste levels increasing in line with a growing population, organic waste facilities have their work cut out to meet capacity. Investment in in-vessel composting facilities, including containers, silos, agitated bays and enclosed halls has soared. Still, an often unspoken aspect of organic waste treatment – odour control – has seen soaring investment too. […]

Read More

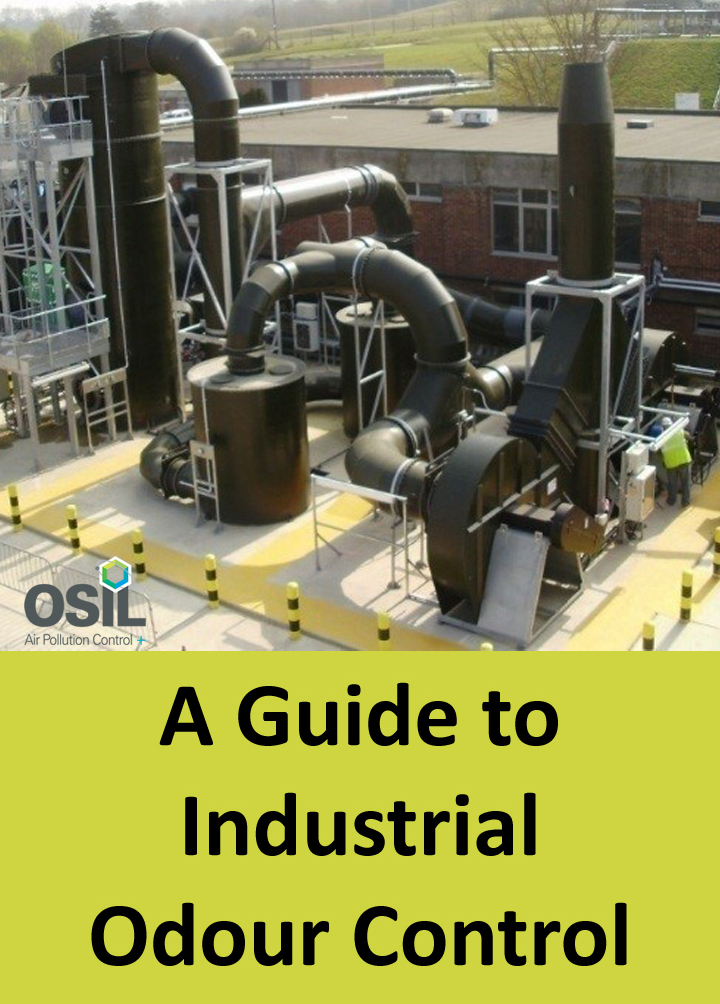

A guide to Industrial Odour Control Solutions

Find out everything you need to know about Industrial Odour Control Solutions. Odours are a by-product of many industrial processes, including wastewater treatment, incineration, crude oil refinement, chemical processing and food production. These odours become a problem when they cause a nuisance. This can lead to complaints and attract attention from councils who can serve […]

Read More

Why optimise your service and maintenance strategy?

Service and maintenance is all about making sure things work properly, but there’s a lot more to it than simply scheduling appointments. Companies that are serious about their air pollution, ventilation and odour control systems need an optimised service and maintenance strategy. What is a service and maintenance strategy? It’s a strategy that defines your […]

Read More

Celebrating Clean Air Day with CO2 Removal Technology

Clean Air Day UK is upon us! What better time to build awareness of air pollution? Every year in the UK, 36,000 deaths are linked to air pollution. Studies have linked air pollution to cardiovascular diseases and lung cancer. There is even evidence from the World Health Organization linking it to Alzheimer’s disease and dementia. […]

Read More

Downflow Gas Contactor (DGC) Technology is the Future for Carbon Capture

We are using more renewable energy in our power grid than ever before, with wind, sunlight and hydro making up 42% of the UK’s electricity in 2020. This is a great step in reducing carbon emissions across all industries, but we cannot decarbonise our economy fully without capturing the carbon dioxide (CO2) produced by industry. […]

Read More

Odour control for industrial emission treatment

When not controlled adequately, industrial emissions cause significant air pollution, and odorous compounds in these emissions can lead to community complaints and abatement notices from your local council. This makes odour control a key consideration for industrial emission treatment, no matter the scale of the operation. The following odorous compounds are common in industrial emissions: […]

Read More

9 Reasons Why Odour Monitoring is Crucial

Odour monitoring is a scientific process that aims to detect and collect data about problem odours such as intensity and type. It is crucial in industrial and commercial odour control for a variety of reasons. Here are the 9 main reasons: It empowers every odour management plan Odour monitoring will form a crucial part of […]

Read More

Odour Management for Organic Waste Facilities

Organic waste facilities produce a variety of foul odours, with gaseous ammonia (NH3) and hydrogen sulphide (H2S) being the biggest culprits. Potential sources of odour in organic waste facilities include: Composting activities Foul surface water Residual wastes for landfill Storage prior to processing Odour management for organic waste facilities involves reducing odorous gases that are […]

Read More

Passive Filter in Industrial Odour Control

If your industrial operation generates noxious/toxic organic gases, passive filters are the simplest way to filter vent gases on storm, sludge, sewage and waste holding tanks, fume exhaust cupboards and pump sumps under positive pressure. We typically specify passive filters when there is a need to vent otherwise noxious and unpleasant gases out into the […]

Read More

Servitisation and Financial Models for Odour Control Systems

When you buy plant outright, you are tasked with looking after it. This puts a barrier between you and the manufacturer, limiting the value you could get from working more closely with them to make your plant work better. A solution to this is servitisation, an asset procurement model where instead of buying assets outright, […]

Read More

Carbon Neutrality Innovations in Odour Control

Carbon neutrality, or net zero carbon, means finding a balance between emitting carbon and absorbing carbon from the atmosphere. There are several ways businesses can reduce emissions without affecting operations, but getting to net zero is a significant challenge, especially for manufacturers like us who have a lot of direct and indirect emissions. Despite the […]

Read More

The benefits to Lease Hiring and Lease Purchasing Standardised /Containerised Plants

OSIL offers a range of standardised / containerised odour control solutions that are ‘plug and play’ and ready to go. These solutions enable rapid deployment with significantly less engineering time while delivering incredible performance. We offer you three ways to buy containerised plant: 1) Outright purchase, 2) Lease purchase, 3) Lease hire. Options 2 and […]

Read More

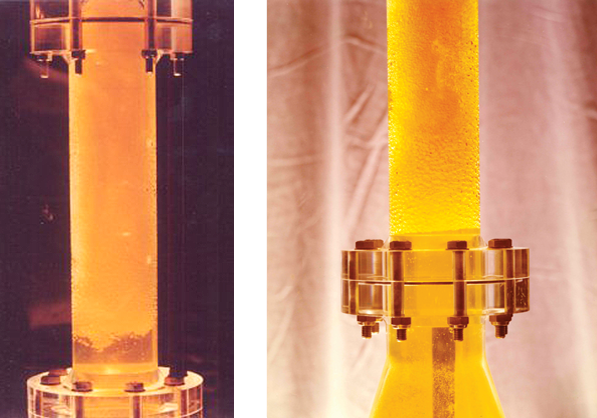

How Odour Monitoring, Sampling and Analysis works?

When odour management decisions are based on nothing but guesswork this often results in incorrectly specified odour control systems. This shouldn’t come as a surprise. After all, how could anyone select and size the correct odour control system without knowing anything about the odours? That would be like trying to fix a car without understanding […]

Read More

Odour Monitoring in Biogas Projects

Odour monitoring in biogas projects is an essential stage of odour management. It is necessary to ensure that biogas production does not impact the local population. It can also help us locate and identify inefficiencies in equipment. Biogas and odours Because modern biogas production takes place in a hermetic environment, biogas plants shouldn’t produce unpleasant […]

Read More

Wastewater Odour Control: An Evolution of Technologies

Wastewater treatment plants produce significant volumes of odour that must be treated before contaminated air can be exhausted outdoors. Most odours produced during wastewater treatment result from anaerobic decomposition of organic matter. Sulphur, nitrogen and methane are released during this process, as are H2S and ammonia. The result is a potent mix of gaseous […]

Read More

Industrial Odour Control Systems And Solutions

We might be pointing out the obvious, but the best odour control system is the one that works. Different odours call for different solutions and the type of work you do, including the equipment you use, will determine the design of your system. Design and Build We offer a complete design and build service to […]

Read More

Odour Complaints and How to Respond Objectively?

Odour complaints come in two forms. The first is complaints directly from people in the community including neighbours / local residents and / or local businesses. This is often the first stage of a complaint. It represents an opportunity to address the problem early so it does not escalate and cause further annoyance. The […]

Read More

How To Control Food Factory Odours

Food factories generate significant volumes of odour the most offensive of which is hydrogen sulphide gasses (H2S). This smells like rotting eggs and is intolerable. Food processing also generate VOCs, aldehydes, ketones, alcohols, acids, ammonia, amines and mercaptans which can be equally offensive. Add fats, greases, sludges, slurries and high temperatures to the mix, and […]

Read More

Where can odour control be used?

Odours are a by-product of many industrial processes, including wastewater treatment, incineration, crude oil refinement, chemical processing and food production. These odours become a problem when they cause a nuisance. This can lead to complaints and attract attention from councils who can serve an abatement notice. There are several technologies we can use to control […]

Read More

What Are The Best Odour Control Solutions?

To achieve a desired level of odour control it is necessary to select and size the correct odour control system, and the filtration technologies specified will determine what odours are removed and the removal efficiency. Some of the best odour control solutions we offer include chemical scrubbers (ChemKlean®), biological (LavaRok®) filters, OdaCompact® systems, Hi-Flow CuCarb […]

Read More

What Are the Benefits Of Implementing Odour Control?

Industrial premises and wastewater treatment plants create odours as a by-product of operating. This can’t be helped. However, these unpleasant odours can be removed or controlled to reduce their presence in the environment. Why would you want to do this? There are several reasons why it’s a good idea. Here are the benefits of implementing […]

Read More

How Industrial Companies Can Use Odour Control To Reduce Negative Impact On The Environment

When industrial odours aren’t controlled they pollute the local environment. This is unpleasant for members of the public and other local businesses. It can also create poor working conditions that affect employee health and morale. From an environmental perspective, air pollution is bad news because it affects the quality of the air we breathe. While […]

Read More

How to Maintain an Odour Control System

Service and maintenance is key to ensuring that your odour control system continues to work as intended and is safe to use. Without service and maintenance, your odour control system will be susceptible to problems like failing components, a build-up of residue (limescale, sludge, etc.) in scrubbers and vessels and electrical and mechanical bugs. These […]

Read More

Common Problems in Odour Control

Problem odours are a by-product of many industrial processes such as wastewater treatment, incineration and chemical processing. These odours must be controlled to minimise their impact on the environment. The common problems in odour control include: How to define and characterise what odours are being produced Selecting and sizing the correct odour control system Creating […]

Read More

Happy Christmas

OSIL will be closed for Christmas from 24th December and reopening on 4th January 2021.Wishing you all a Happy & Safe Christmas.

Read More

Odour control in sewage treatment

Sewage treatment plants must route odours through odour control systems to control air pollution. Ventilation systems are useless on their own for odour control if all they do is vent odours out into the atmosphere. This setup would only pollute the atmosphere and cause a nuisance with the local population. It may even get you […]

Read More

LEV & GEV Surveys

Where a business produces airborne contaminants in the workplace, there is a legal and insurance-based requirement to protect workers’ health by controlling exposure to contaminants. Control is achieved with an LEV or GEV system. The question of whether LEV and GEV surveys are necessary is a plain matter of requirement. HSE’s Control of Substances Hazardous […]

Read More

The Consequences if Odour Control isn’t implemented

Wastewater treatment, chemical processing, waste incineration and food production can all contribute to industrial odours. Many industrial sectors and municipal wastewater treatment works can release unpleasant odours into the air which can travel for miles before becoming a nuisance. Different environmental factors can also play a key role in increasing the effect of offensive odours. […]

Read More

Odour Masking Vs Odour Control

It is a common misconception that these two terminologies are identical to each other but in reality, they are poles apart. We at OSIL are here to guide you through the differences. Odour Masking The simplest comparison of industrial Odour Masking is the domestic air-fresheners when introduced into a room at a high concentration they […]

Read More

Case Study: United Utilities

Tube Vent Units Project Description New storm tanks have been installed in and around Oldham. Vents were needed to allow air to be drawn in when the storm tanks were been emptied and air to be pushed out when they fill up. When this air leaves the storm tank it could be odorous and this […]

Read More

See our latest newsletter

In our latest newsletter we announce the launch of our financing packages for our Odour Control solutions Find out more about Odour Control financing

Read More

Moving forward with COVID-19

Putting People First Due to the rapidly evolving situation with coronavirus (COVID-19), we would like to give some clarity and reassurance on how we intend to operate for the foreseeable future. OSIL will continue to operate at full capacity in order to support you on a day-to-day basis. We are aware of the strain being […]

Read More

CORONAVIRUS – Lockdown Update

UPDATE: All our office based staff are now working from home. Employees can be contacted on their mobile phones or by email. Individual contact details can be found by visiting our Contact Us page. Alternatively, you can contact us on our emergency number 0330 020 0270.

Read More

How Does Odour Control Work?

A lot of people don’t realise that waste handlers and other industrial environments deal with a wide array of unpleasant odours on a daily basis. Not only can these fugitive emissions make it difficult for people to work, but they can also travel in the air with the right meteorological conditions causing a nuisance to […]

Read More

ISO27001

Martin Degg joins OSIL

We are pleased to welcome Martin Degg in the role of Project Manager. Martin will be another great addition to the growing OSILTeam.

Read More

Case Study: May Gurney

Whitlingham SBT, Odour Abatement System: LavaRok® Biofilter, CuCarbs®, Fans, Ductwork & Covers Project Description Odour abatement of H2 S and ammonia extracted from covered tanks through an OSIL LavaRok® Biofilter followed by dual CuCarb® activated carbon polishing units capable of a 99% removal of 30ppm NH3 and 100ppm H2 S from a 12,500mÑ/h air stream. Final effluent water is continually sprayed over the graded LavaRok® pebbles to […]

Read More

OSIL rapid response service team complete critical carbon change

OSIL were awarded the emergency changing of carbon media inside two carbon filters that serve the Thermal Hydrolysis Plant at a Thames Water site. The existing media installed on site was under performing to significantly reduce the sulphur compounds that are treated by the odour control plant. After undertaking a system survey OSIL recommended the […]

Read More

Achilles Audit – updated certificate

Case Study: Timothy Taylor & Co. Ltd

Keighley Brewery – Odour Control Plant Project Description OSIL were invited to design, supply and install an odour control plant to capture and treat the odours from Timothy Taylor’s new effluent plant. The system was designed to extract 1,550m³/h from the sludge thickening building and comprises a range of interconnecting ducting, an extraction fan and […]

Read More

Gareth Smith Joins OSIL

OSIL are pleased to welcome new OSIL team member Gareth Smith in the role of Project Engineer. Gareth will be a great addition to the Projects Team.

Read More

Tyler Dutton Joins OSIL

We are pleased to welcome our newest OSIL team member, Tyler Dutton in the role of 3D CAD Modeller/Designer. Tyler will be a great addition to the OSILTeam.

Read More

Ken Cockram Retires

Ken Cockram, (Proposals Manager) retired the end of June after 8 years service with OSIL. Ken introduced some very useful procedures to the Company. We will all miss him, but hopefully he’ll pop in and see us from time to time. Enjoy your retirement Ken.

Read More

Mark Wenlock joins OSIL

Our latest recruit is Mark Wenlock. Mark joins us in the role as Site Engineer. Mark has a wealth of experience and will be an asset to the Company.

Read MoreRon Hayden & Bill Thompson join OSIL

We are pleased to welcome new OSIL team members Ron Hayden & Bill Thompson in the role of Service & Maintenance Engineer and Project Engineer respectively. The company has continued to grow in regular service & maintenance of odour control systems across the waste water industry, the appointment of Ron & Bill will further provide […]

Read More

Achilles UVDB Certification

We are pleased to announce for the third year running that OSIL have been awarded the Achilles UVDB Verify Audit Certification, Category B1, achieving an amazing 100% in all four categories! We are all proud to be part of such a fantastic result.

Read More

Ashley Copper Joins OSIL

OSIL are pleased to welcome new OSIL team member Ashley Copper in the role of Site Engineer. Ashley will be a vital role in Site, Service and Maintenance for our clients

Read More

How OSIL Solved South West Water’s Odour Control Problem at Mill Bay

How may you ask did OSIL solve the problem that South West Water were experiencing with their odour control system at Mill Bay? Well firstly, SWW came to the right place. Odour Services International Ltd has years of experience in this specialised industry. Initially a site visit and an examination of the existing vessel was […]

Read More

OSIL attends 2017 British Water Charity Golf Day

OSIL attended British Water’s Charity Golf Day, supported by Water Active, on 29th June at Luton Hoo Hotel Golf and Spa Resort. This year’s Winning Team included Roger Tucker from Viking Johnson, Matt Rolls representing Evoqua Water Technologies and our Neil Cunliffe and Matt Wilkes of Odour Services International Ltd. This is the fourth year in […]

Read More

OSIL complete odour control system media changes for Wessex Water

Even the infamous ‘Storm Doris’ that moved rapidly over the UK on Thursday February 23rd was unable to keep OSIL from completing the media change works on schedule much to the satisfaction of Wessex Water. OSIL were awarded the changing of carbon and shell media at several sites within the Wessex Water north, south and […]

Read More

OSIL achieve highest accreditation score with Achilles UVDB Verify Category B1 todate

Achilles – UVDB – Verify Audit Certificate 2017-18 Odour Services International Limited (OSIL) are pleased to announce that it has been awarded an Achilles UVDB Verify Category B1 Accreditation for the second year in succession. The accreditation was awarded following a rigorous independent audit and evaluation of our Head Office and Site Management Systems and […]

Read More

OSIL awarded ISO 9001:2015 accreditation

OSIL ISO 9001:2015 Certificate of Approval OSIL are pleased to advise that we have successfully achieved approval to ISO9001:2015. OSIL received accreditation from LRQA on 23rd January 2017. This accreditation certifies OSIL’s quality management systems under the terms set out under United Kingdom’s Accreditation Service (UKAS). The accreditation was the result of a thorough quality […]

Read More

Emergency ductwork repair works completed

As all good emergency works are required OSIL received a request late last week to urgently repair ductwork that had significantly split on a large odour control system in Thames Water. The split had occurred at a segment joint of the 1 meter diameter 90 degree bend. The case of failure was due to ductwork […]

Read More

OSIL complete installation of new odour covers & doors

OSIL have completed the installation of new odour covers & doors at Slough Sewage treatment works. Prior to the install odours had been able to escape from various areas on site without going through the treatment of an odour control system, now that the new covers are in place the odours can be treated to avoid […]

Read MoreHello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

Read MoreOSIL complete extension & re-siting of odour control ductwork for Thames Water

Congratulations to our hard working site team was well earned this past week, OSIL were awarded the design, manufacture, delivery and installation of the substantial extension & re-siting of ductwork on a process critical odour control system for Thames Water. The newly sited ductwork route was undertaken by OSIL engineers to facilitate the incorporation of additional […]

Read More

New installation of OdaCompact System complete

OSIL completed installation of our new OdaCompact System at Whitlingham Sewage Treatment Works.

Read More

OSIL attend British Water’s Annual Charity Golf Day

It was a successful third year running for one of our directors at the British Water’s Annual Charity Golf Day at Bowood Park Golf Club in Wiltshire. Matt Wilkes has been part of the team that has won the team prize for the last three years with the added bonus of securing the individual prize […]

Read More

OSIL complete time critical weekend carbon media change

The first weekend of July was a busy one for the OSIL site team as they carried out a carbon media change at one of the UK’s leading food companies after media sample & analysis determined the deterioration of the carbons adsorption capacity. OSIL programmed & delivered the time critical work all within 2 weeks […]

Read More

Neil Cunliffe joins OSIL

OSIL are pleased to announce that Neil Cunliffe has joined us in the role of regional service & maintenance manager. The company has continued to grow in regular servicing of odour control systems, Neil has a wide range of experience in having previously worked with Thames Water for over 30 years. His process knowledge and […]

Read MoreThe benefits of planned service and maintenance

OSIL believes the key to achieving optimum operating efficiency is underpinned by a planned, routine Service and Maintenance regime. In addition to performance related benefits, customers embracing this service have seen significant cost savings and improved relationships with regulators, local authorities and nearby residential areas. Planned maintenance programmes are designed to ensure that any potential […]

Read More

‘WIL-KO’ ready for big bout

OSIL Project Engineer Matt Wilkes spends most of time during the week helping clients to combat odour and air pollution. But, on Saturday, he will be hoping to benefit from a few fresh air shots himself when he takes to the boxing ring for the first time. After three months of rigorous training Wilkes, […]

Read MoreOSIL Complete South West Water Refurbishment Works

OSIL have completed odour control refurbishment works on several sites within South West Water. The works included both shell and carbon media changes. Removal of the old faulty existing Control Unit, irrigation pipework upgrade, modification of the existing ductwork and stack and installation of a new Cucarb® Deep Bed Filter. Marcus Rose and Ron Hayden […]

Read More