We would like to take this opportunity to wish everyone a Happy Christmas and a Healthy and Prosperous 2024 from all the Team at OSIL.

Our office will close for Christmas from Friday 22nd December and reopen on Wednesday 3rd January 2024.

We would like to take this opportunity to wish everyone a Happy Christmas and a Healthy and Prosperous 2024 from all the Team at OSIL.

Our office will close for Christmas from Friday 22nd December and reopen on Wednesday 3rd January 2024.

We would like to take this opportunity to wish everyone a Happy Christmas and a Healthy and Prosperous 2023 from all the Team at OSIL.

Our offices will be closed on Friday 15th and Monday 18th April 2022 for the Easter Holidays. We will reopen at 9am on Tuesday 19th April. Enjoy the long weekend and Happy Easter.

Wishing you all a Merry Christmas & a Happy New Year.

We will close for Christmas on Friday 24th December and reopen on 4th January, 2022.

Carbon neutrality, or net zero carbon, means finding a balance between emitting carbon and absorbing carbon from the atmosphere.

There are several ways businesses can reduce emissions without affecting operations, but getting to net zero is a significant challenge, especially for manufacturers like us who have a lot of direct and indirect emissions.

Despite the challenges we face, we recognise our environmental and social responsibilities to reduce harmful emissions from our operations.

That’s why we decided to take action this year to significantly reduce our emissions, following successful pilot initiatives and in-depth assessments of where our emissions come from. This led us to develop a new operational approach.

Our position as a manufacturer led us to the conclusion that the best way to reduce our emissions is to change our design and delivery approach to manufacturing and services, so that we and our clients benefit from our initiatives.

This is why we have adopted a new design and delivery approach which is designed to slash carbon emissions across our manufacturing operation and the lifecycle of our odour control systems. This will ensure maximum results are achieved.

Our initiatives include:

Some of our clients, including Suez Recycling & Recovery Ltd, Argent Energy Ltd., and the majority of the UK Water Companies, are already benefitting from this new approach which is helping them meet their own environmental goals.

Our standardisation initiative led to the development of our Containerised Hi-Flow CuCarb Odour Control Units. These units are pre-built and are ready to use on-site immediately with no downtime and small emissions from setup.

This initiative includes refurbishing and moving redundant plant from one facility to another where it can be re-used, recycling airflow to get a more thorough treatment with the same units, and recycling carbon media so no waste goes to landfill.

We are also developing smaller, more efficient odour control systems that use fewer materials by engaging with clients to provide systems designed for operating conditions rather than theoretical bench studies.

This initiative allows our clients to acquire new, state-of-the-art odour control systems that make use of the most efficient technologies through a lease/hire initiative. This ensures they can invest in the greenest systems without breaking the bank.

Our lease/hire agreements have several financial advantages, including predictable monthly / quarterly payments, low interest rates, and tax and funding initiatives to reduce asset capital values on business books with offsets for tax initiatives.

We have developed servitisation options for our clients so that our products and services can be provided as a single integrated solution.

Services like maintenance, servicing, spare parts, emergency call outs, troubleshooting and upgrades can be provided as a service within a single contract. This reduces emissions by streamlining product care, service requirements and more.

Together, these carbon neutrality innovations can help your organisation slash emissions while meeting your odour control requirements. Contact us to find out more.

Odour complaints come in two forms. The first is complaints directly from people in the community including neighbours / local residents and / or local businesses.

This is often the first stage of a complaint. It represents an opportunity to address the problem early so it does not escalate and cause further annoyance.

The second is when a company’s response to the odour problem isn’t sufficient, the local council can get involved and serve an abatement notice. This could require whoever’s responsible to take steps to resolve the problem, stop the activity, or limit the activity to certain times.

It’s important to have an effective and transparent procedure for handling complaints. This will ensure complaints are handled quickly and appropriately.

Responding to odour complaints is one of the trickiest aspects of complaint handling because people expect a reasonable response. They want a solution. Here are some tips on how to respond to complaints objectively:

Upon receiving a complaint, you should log and acknowledge the complaint. This is an opportunity to show the complainant you are doing something about it. It’s good practice to respond in writing but email or telephone is fine too.

Some companies only respond to complaints when two or more complaints are logged describing the same problem.

This helps validate if there is an issue, but it’s only satisfactory for minor complaints. You also run the risk of causing great annoyance if you take too long.

It can be prudent to investigate single odour complaints if they are serious enough. For example, sewage odour complaints could be a sign of a serious problem like a broken sewer or vent stack. In these situations, investigations should be hurried.

Investigations sometimes need to be immediate. A good example is complaints involving the smell of gas.

Use your expertise to determine when an odour complaint should trigger an immediate investigation or when a volume approach is best.

Odour complaints demand action if you intend to resolve the problem. This can only be achieved by investigating the complaint. The complaint should be assigned to designated personnel for investigation and resolution.

Odour complaints can be investigated in several ways:

Once you have a clear picture of the cause of the odour nuisances you can come up with solutions. These could include:

Some complaints will have simple fixes while others will require investment.

What’s most important is you take accountability for complaints and try to resolve them. Communicating with complainants throughout this process is also key. The last thing you want is your local council to serve you an abatement notice.

If you are on the receiving end of odour complaints and you are struggling to resolve the problem, we can help. Speak to one of our odour control experts today about how we can help you by calling (0) 1543 506855.

To achieve a desired level of odour control it is necessary to select and size the correct odour control system, and the filtration technologies specified will determine what odours are removed and the removal efficiency.

Some of the best odour control solutions we offer include chemical scrubbers (ChemKlean®), biological (LavaRok®) filters, OdaCompact® systems, Hi-Flow CuCarb Units and Passive Filters.

When the correct filtration solution is specified, up to 99% removal efficiencies can be achieved in many applications. The best odour control solution to meet your requirements depends on the type and character of the odours you produce.

ChemKlean® is the technology of choice for basic odour control applications because it’s simple but effective. Wet scrubbers remove odours from air gas streams using a chemical liquid absorbent.

We can also specify multi-stage scrubbers. These can remove higher concentrations of odours as well as diverse odours like amines and mercaptans. Some multi-stage wet scrubbers use two or more liquid absorbents with different properties while others use a dry media filter for insoluble VOC removal and final polishing.

LavaRok® is a biological filter made from pumice stone. Microorganisms (bacteria) grow on the pumice stone to form a bio-film. The biology and ecosystem of the microorganisms can be designed to treat a wide range of odours.

LavaRok® is a modern substitute for woodchip and shells in biofiltration, it promotes a diverse bio-film where good bacteria can flourish. LavaRok® also boasts a 25-year lifespan with low running costs and low maintenance.

Passive filters are activated carbon-based odour control filters most commonly used to absorb vent gases from sewerage processes. They can absorb hydrogen sulphide and other noxious odours produced in sewage treatment.

We typically specify passive filters for storm, sludge, sewage and waste holding tanks, fume exhaust cupboards and pump sumps under positive pressure. We can also specify them for VOC removal in oil storage tanks.

These can be delivered in a range of construction materials and we offer a bespoke design service to suit your environment. Disposable or re-fillable filters are available – as well as a powered vent option.

Our Passive Filter Systems can even be disguised as trees, bollards and lamp posts where odour control is required in sensitive areas.

OdaCompact® is an innovative odour treatment unit that performs two stages of odour treatment in a single tower. It combines LavaRok® biofiltration with CuCarb® dry media filters in a space-saving design. It’s chemical-free and low-maintenance.

In this system, the first stage is LavaRok® biofiltration where the microorganisms metabolise / neutralise odour compounds. The second stage is carbon filtration where the odour compounds are converted into non-odorous metallic compounds.

The OSIL Hi-Flow CuCarb Unit is a modular odour control solution capable of treating airflows from 6,000 to 45,000m3 /hr. It uses activated carbon adsorption with CuCarb® filters and it’s easy to service with straightforward media replacement.

This odour control solution is available to buy or rent from us and can be configured with a wide choice of ductwork as well as insulation. The units can also be stacked to treat more airflow. The biggest benefit to this technology is it treats large airflows with a proven media technology in a standard footprint. It’s a ‘ready-made’ solution.

Want to find out more about these odour control solutions? Contact us today and speak with one of our experts. Just call +44 (0) 1543 506855.

Industrial premises and wastewater treatment plants create odours as a by-product of operating. This can’t be helped. However, these unpleasant odours can be removed or controlled to reduce their presence in the environment.

Why would you want to do this? There are several reasons why it’s a good idea. Here are the benefits of implementing odour control:

Wastewater treatment, chemical processing, waste incineration and food production are leading causes of industrial odours. If your business produces odours, quality control over your process dictates that odour control is necessary.

It probably won’t surprise you to know that there are reputable companies out there who do not have adequate odour control. These companies will have to get their houses in order eventually with a fit-for-purpose odour control system.

Unpleasant odours generate complaints. This is bad for your reputation and it could be bad for business. If odours are not controlled, you will eventually attract attention from the local council who could serve an abatement notice.

An abatement notice requires whoever’s responsible for the odour to either eliminate it or restrict it. The only way to achieve this is with an odour control system. If complaints are not addressed then you could land yourself in legal trouble.

No one wants to live with unpleasant odours and being subjected to them can cause resentment. Whether your neighbours are homeowners or businesses, you have a duty to minimise the impact of your operations on them.

Implementing odour control will keep your neighbours happy by allowing them to enjoy their homes and run their businesses. Ask yourself this: would you want to live or work near a place that produces noxious odours? Probably not.

Your employees keep your operation moving. Providing a good working environment for them is essential for their health and wellbeing. Odour control will be necessary if employees work in places that are susceptible to odours.

It’s also important to point out that employers have a legal duty of care for their employees. Odours may appear to be nothing more than annoyances, however for people with asthma and underlying health problems, they could be hazardous.

Following on from our previous point (that employers have a duty of care for employees), the Control of Substances Hazardous to Health (COSHH) Regulations are designed to ensure that damage to health from hazardous substances is controlled.

VOCs and vapours are prime examples of hazardous compounds that have to be controlled under health and safety legislation. If you produce odours and compounds that are harmful to health, you have a legal responsibility to control them.

If you need to implement odour control in your business, OSIL can help with our industry-leading range of odour control systems and finance solutions. To find out more, call us today on (0) 1543 506 855 or email us at info@osiltd.com.

OSIL will be closed for Christmas from 24th December and reopening on 4th January 2021.Wishing you all a Happy & Safe Christmas.

Sewage treatment plants must route odours through odour control systems to control air pollution. Ventilation systems are useless on their own for odour control if all they do is vent odours out into the atmosphere.

This setup would only pollute the atmosphere and cause a nuisance with the local population. It may even get you in trouble with the local council. For these reasons, odour control should be a top priority for all treatment works.

The most common cause of a foul odour in sewage treatment plants is the release of hydrogen sulphide (H2S). This offensive odour is also known as “sewer gas” and it can cause health problems.

Other types of odours include amines which possess an ammonia smell and mercaptans which give off the stench of rotting food.

Sewage moves through pipes and is treated by a number of processes contained in large tanks. This environment is contained. The screenings and sludges are separated and pumped away into containers. Again, the environment is contained. So, you might be wondering how odours escape and make a plant smell?

The main cause is biological overload and odour overload. Quite simply, tanks and process rooms have to be ventilated and sludge has to be removed at least once a year and tanks have to be cleaned. This can allows odours to escape. Plants can also have spills and accidents that can also cause significant odour problems.

Controlling odours so that they are not a problem for the local population is important for several reasons, chief of which is a social responsibility to ensure that your operation does not impact on the lives of local residents.

Thankfully, there are a number of odour control systems we can use in sewage treatment plants so that the air vented is clean and odourless.

Some of these systems include:

These are an activated carbon-based, passive odour control unit. They are commonly utilised to absorb vent gases from sewerage processes.

Our CuCarb® activated carbon dry scrubbers can operate as a single standalone unit or as a polishing unit downstream of biological or chemical treatment systems. OSIL’s selected activated carbons serve as media to purify air streams by concentrating and retaining odorous gases and vapours.

Our ChemKlean® Scrubbing System has no moving parts to reduce maintenance. This system works by using a liquid to absorb odour-causing components in gasses. The gas is then released into the atmosphere.

Dual systems combine two systems for odour control, such as biofiltration + carbon filtration or chemical scrubbing + carbon filtration. We call this process multi-stage filtration, and it is used to control powerful odours.

The scale of your operation, the types of equipment you use, and the design of your building and ventilation system will determine the right solution. There is no one-size-fits-all approach. It’s important to note that the size of the systems used in odour control vary. You need bigger systems for higher air volumes. We can recommend a few options if you’d like. Feel free to call us on (0) 1543 506855 for a chat.

Where a business produces airborne contaminants in the workplace, there is a legal and insurance-based requirement to protect workers’ health by controlling exposure to contaminants. Control is achieved with an LEV or GEV system.

The question of whether LEV and GEV surveys are necessary is a plain matter of requirement. HSE’s Control of Substances Hazardous to Health Regulations state businesses have a legal obligation to control dust and fumes.

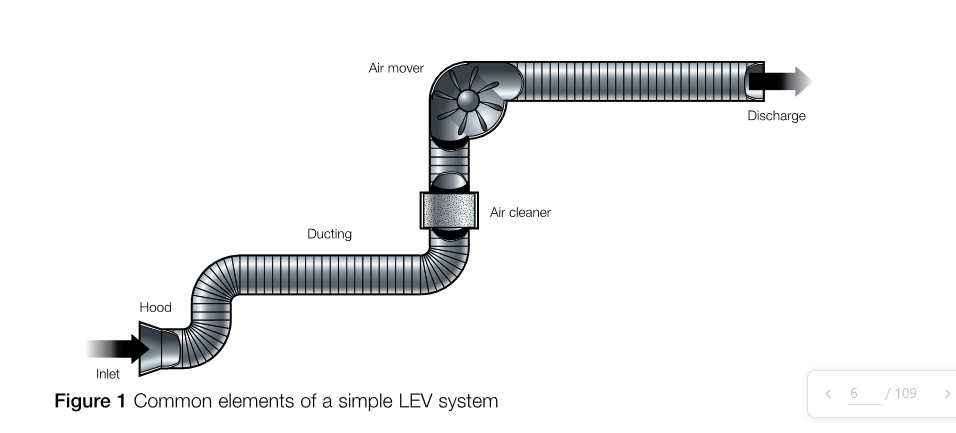

LEV and GEV systems are used to extract and ventilate airborne contaminants and pollutants (e.g. dust, fumes and gas). These systems require regular checks to ensure they are fit for purpose, and surveys enable compliancy to be checked.

Health and safety law, says you must assess the risks to your workers from hazardous substances – dusts, fumes, vapours, etc. – and decide what measures to use to protect their health.

If the measures you adopt include extraction systems (LEV) to remove the dusts, fumes, vapours etc. produced by your work processes or activities, then you must maintain the LEV in efficient working order, so it continues to provide the necessary protection. You should also have a periodic thorough examination and test (at least every 14 months) and must keep this record for at least 5 years. In addition, you should have information on the installed LEV system to confirm it provides adequate protection, which should be kept for the life of the equipment.

You must ensure that your LEV is still working as effectively as originally intended and is helping to protect your employees’ health. To be able to tell if it is still working as it should, you should be able to provide the examiner with information about the intended or designed performance of your system.

An examination will test:

Each piece of LEV / GEV equipment in a system is inspected to ensure system conformity with design specifications. The system is then tested to establish if it provides an adequate level of exposure control.

This information might be in the form of an initial appraisal or commissioning report, if one was carried out, or for simple ‘standalone’ systems it could have been provided as standard operating data by the suppliers of the extraction equipment. Alternatively, it might be found in recognised guidance (including that from HSE) on simple processes/systems (For example LEV Guidance hsg258 ). If none of this is available, you could consider getting someone competent to advise you.

During a survey, extraction systems are visually inspected and tested to determine if they are fit for purpose and functioning as intended.

LEV and GEV surveys produce a report that highlights defects, problems and advises where maintenance is recommended. Businesses must implement critical recommendations to comply with health and safety standards.

For example, the survey may find an issue with ducting that leaks. The ducting would need to be repaired or replaced for the system to pass the test.

Businesses must also keep records of all examinations and tests for at least five years. A logbook or dedicated LEV/GEV file is the standard way of doing this. Following a survey, the survey report should be read, and any queries/actions addressed. A presentation of the survey should be carried out to the client from the examiner, if possible. If a logbook is used, then this should be stamped so the business has a record of compliance.

Another important aspect of surveys is ensuring the people who use the extraction system know how it functions and what settings have been established during the commissioning process. Training should be provided by the installer in this respect. Adjustments to any settings should not be made by anyone except the company’s maintenance engineer, the commissioning engineer or the LEV system examiner.

Routine checks (maintenance)

Regular LEV and GEV surveys are a legal requirement, so you are breaking the law if you have a ventilation system that isn’t regularly tested.

To put it another way, surveys are necessary to determine the ventilation system is functioning as intended and providing the necessary protection against airborne contamination. They will also detail the requirements to prove compliance with health and safety legislation.

If you require assistance with your LEV or GEV surveys OSIL would be pleased to discuss your requirements.

Wastewater treatment, chemical processing, waste incineration and food production can all contribute to industrial odours.

Many industrial sectors and municipal wastewater treatment works can release unpleasant odours into the air which can travel for miles before becoming a nuisance. Different environmental factors can also play a key role in increasing the effect of offensive odours. One of the common examples that intensifies odour at the source is an increase in the air temperature and air distribution can also transfer odours from one place to another.

Continuous odour emissions of a pungent type can be categorised as a part of air pollution and such odours can have a detrimental effect on local neighbourhoods. Constant exposure to offensive and aggressive odours inside a factory, food manufacturing facility or waste treatment plant can cause severe mental and physical health problems to the employees as well as causing detrimental corrosion to plant and machinery.

A large number of research studies have suggested that odour emissions could be more dangerous to the most susceptible sections of the population. It can particularly affect; children, the elderly and asthmatic sufferers. The correct type of odour control can lead to a better and a healthier environment for people living in the neighbourhood of a plant that is producing foul odour.

The offensive release of harmful gases like hydrogen sulphide, ethyl methyl sulphide and trimethylamine can result in serious health issue. These health issues can produce symptoms that range from mild discomfort, to being extremely serious. Chemicals with strong odour have the capacity of causing lung, eyes, nose and throat irritation. Employees working inside factories can experience a mild burning sensation in their throat that eventually leads to coughing, wheezing and other breathing problems.

There are a comprehensive range of odour abatement processes that can be used to maintain an odour free environment both internally or externally.

Here is a list of multiple processes that can be used for eliminating odour problems:

With the continual development of towns and cities, foul odour emissions are becoming more and more problematic for all types of manufacturing, production and treatment processes as well as for the conurbations surrounding these facilities.

Odour elimination has gradually become one of the primary concerns that need to be resolved. It is imperative that odour is controlled so as not to materially affect people’s enjoyment of their property or outdoor space and decrease their legitimate use of the environment.

If problems do occur, or are likely to occur in the near future, it is important that the appropriate actions to prevent or minimise the risk are taken. While for some activities it may not be practicable to avoid all odours, any neighbourhood has the right to expect that there must not be any odour produced that will detract from their quality of life. It is unlikely; however, that action will be taken over occasional or slight odours.

By “neighbourhood” we mean anyone living, working, visiting or making use of public space outside a site that is producing odour. It means any sensitive receptor.

Rather than simply installing turnkey equipment, OSIL is one such odour controlling partner that focuses on finding the right solution to resolve odour problems.

Contact us today to find out more about our cost-effective odour control solutions.

It is a common misconception that these two terminologies are identical to each other but in reality, they are poles apart. We at OSIL are here to guide you through the differences.

The simplest comparison of industrial Odour Masking is the domestic air-fresheners when introduced into a room at a high concentration they mask the unpleasant pungent odour present in the room or particular area. As a result, the human nose detects the highly concentrated fragrance and not the bad odour. The drawback to this technique is that the odour still exists in the background and when the masking fragrance fades away, the bad odour resumes its presence, thus demonstrating that it is a short-term solution.

Industrial Odour Masking differs only slightly from the above but is not an entirely unique concept. In the industrial sector, odour masking is achieved by releasing a highly concentrated masking agent in numerous kinds of fragrant odours. The process is used on Industrial Waste, Sewage, Farming, and similar industries to mask the odours being generated. Large areas like septic tanks, sewage ponds, refuse tips, offal processing plants, often use masking agents to deodorise the noxious odour, being produced which would otherwise make the surrounding local area very unpleasant.

There are special odour masking products for the industrial sector that are easy-to-use and can be mixed with water in a range of varying dilutions. As a result, these can be applied by mist machines, sprayers or direct drip-feed into the water source.

Numerous facilities such as sewage treatment plants are prone to odour issues due to the residual components from the treated wastewater. These screenings and sludges can produce an excessive amount of hydrogen sulfide gas which smells like rotten eggs. To control this type of odour, various odour control technologies are used:

The above details the differences between these two odour treatment solutions. We at OSIL can ensure that your employees work in an environment with the best possible atmosphere, one that is odourless and safe from noxious gases. We can help create a workplace environment that employees deserve, reach out to our engineering staff for assistance in removing your odour problems.

In our latest newsletter we announce the launch of our financing packages for our Odour Control solutions

Find out more about Odour Control financing

Whitlingham SBT, Odour Abatement System: LavaRok® Biofilter, CuCarbs®, Fans, Ductwork & Covers

Odour abatement of H2 S and ammonia extracted from covered tanks through an OSIL LavaRok® Biofilter followed by dual CuCarb® activated carbon polishing units capable of a 99% removal of 30ppm NH3 and 100ppm H2 S from a 12,500mÑ/h air stream. Final effluent water is continually sprayed over the graded LavaRok® pebbles to provide the correct environment for the inoculum.

The porous nature of the LavaRok® provides a large surface area for the inoculum to react with the odorous air. The CuCarb® units polish any odour not removed by the Biofilter. The benefit of CuCarb® over other carbons is the ability to continue the polishing process in a damp environment.

“While OSIL presented three options to help us prevent nuisance odours being produced, together with the relative capital and running costs, their LavaRok® bio-filtration system was clearly the way forward. Bio-filtration fits with our business ethics, from the unique long life media to employing natural biological processes.”

Chris Penn, Project Manager May Gurney.

Turnkey design, manufacture, supply, installation and commissioning of OSIL LavaRok® and CuCarb® odour control system including fans, ducting, electrical panels.

Project Duration: 22 weeks

Keighley Brewery – Odour Control Plant

OSIL were invited to design, supply and install an odour control plant to capture and treat the odours from Timothy Taylor’s new effluent plant. The system was designed to extract 1,550m³/h from the sludge thickening building and comprises a range of interconnecting ducting, an extraction fan and a CuCarb® activated carbon unit with an H2S removal efficiency in excess of 99%. To ensure quiet operation the fan is housed within an acoustic enclosure.

Turnkey design, manufacture, supply, installation and commissioning of complete OSIL CuCarb ® odour control system.

Project Duration: 4 weeks

“After analysing our emissions to atmosphere from our new effluent treatment plant we sought a company that could ensure we met exacting standards of odour reduction consistently and cost effectively. OSIL offered us a cost effective practical solution with a high level of industry expertise, design capability and customer service. It continues to work reliably and cost effectively and importantly helps us to meet the high environmental standards set by the company.”

Nick Berkovits, Senior Brewer, Timothy Taylor & Co. Ltd.

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!