OSIL are experienced in Odour and Air Pollution Control Solutions and Services. To find out more about our projects, take a look at our case studies below:

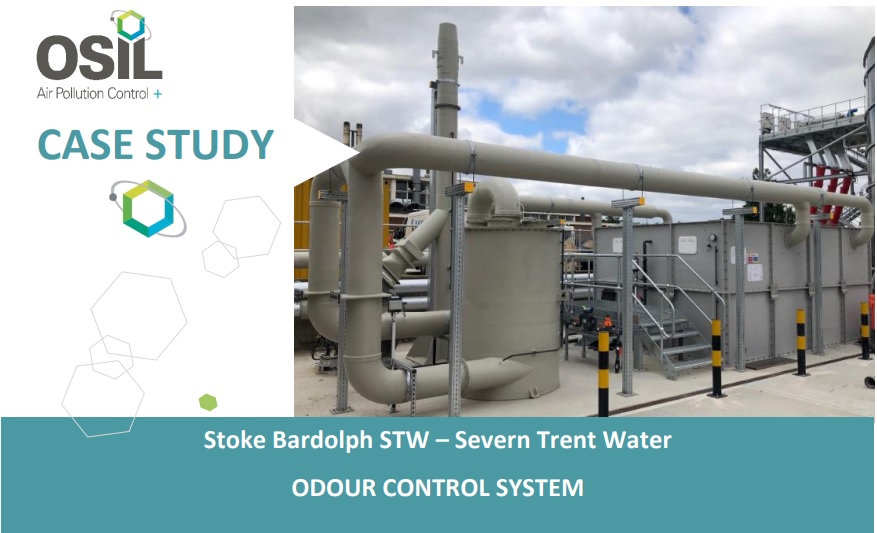

Read our Case Study on Odour Control System at Stoke Bardolph – Severn Trent Water

Stoke Bardolph Sewage Treatment Works is a conventional Activated Sludge Process plant serving a population of circa 620,000. The sites Sludge Treatment facility is a major regional sludge centre. Sludge is digested and dewatered on site with the biogas produced feeding 3 CHP engines plus the produced cake being exported off site. To find out more read our Case Study

Read our Case Study on Acton Manhole Media Change for Thames Water

Odour complaints were received from local residents resulting in investigations of Odour sources. To find out more read our Case Study.

Read our Case Study on Odour Control System at Keighley Brewery

Odour Services International Ltd were invited to design, supply and install an odour control plant to capture and treat the odours from Timothy Taylors’ new effluent plant. To find out more, read our Case Study

Read our Case Study on Odour Control System at Imtech Processes Ltd, Workington

Odour Services International Ltd were invited to provide an odour ducting system to extract hazardous fumes from a newly erected lime sludge blending tank, a cake silo and vehicle loading tunnel. To find out more, read our Case Study

Read our Case Study on Odour Control System at Babock Environmental Eng Ltd

Odour Services International Ltd were invited to install a full size pilot plant to demonstrate the capabilities of our LavaRok technology. The First of Class Pilot Project has been designed and built as proof of concept for BEE’s innovative solution for processing domestic and commercial waste. To find out more, read our Case Study

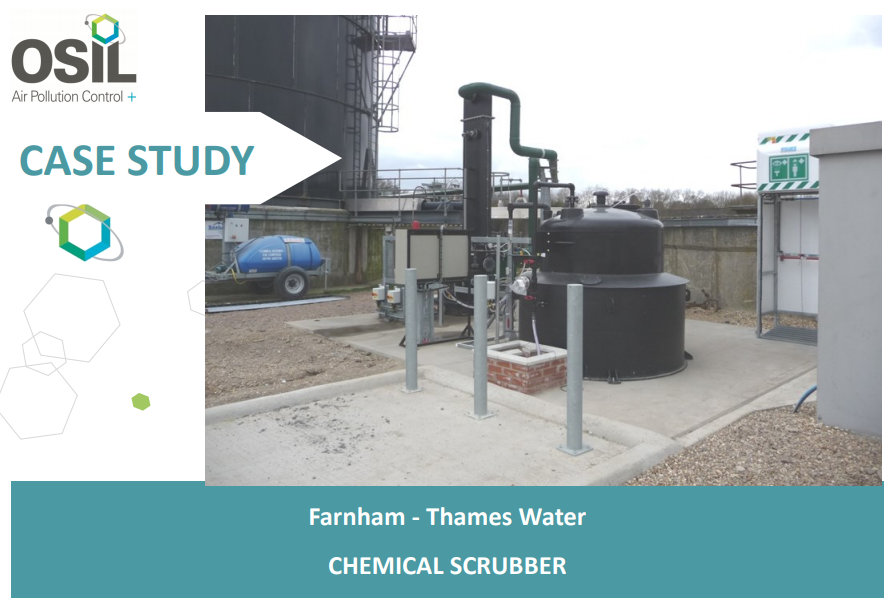

Read our Case Study on Chemical Scrubber at Thames Water, Farnham

Odour Services International Ltd were invited to install a chemical scrubber for treatment of Ammonia from a Lime cake facility at a existing sewage treatment plant. To find out more, read our Case Study

Read our Case Study on Chemical Scrubber at Thames Water, Farnham

Odour Services International Ltd were invited to install a chemical scrubber for treatment of Ammonia from a Lime cake facility at a existing sewage treatment plant. To find out more, read our Case Study

Read our Case Study on OCU Refurbishment at United Utilities, Birkenhead

The client’s odour control system had built up severe sulphur deposits within the chemical scrubber unit, large diameter ductwork sections and irrigation pipework. To find out more, read our Case Study

Read our Case Study on Hull WwTW , Yorkshire Water

Hull Waste-Water Treatment Works treats wastewater arising from the Hull catchment and the Sludge Treatment Facility (STF). Indigenous primary and secondary sludge produced in the STW is thickened and digested along with liquid sludge and cake imported from the surrounding region. To find out more read our Case Study.

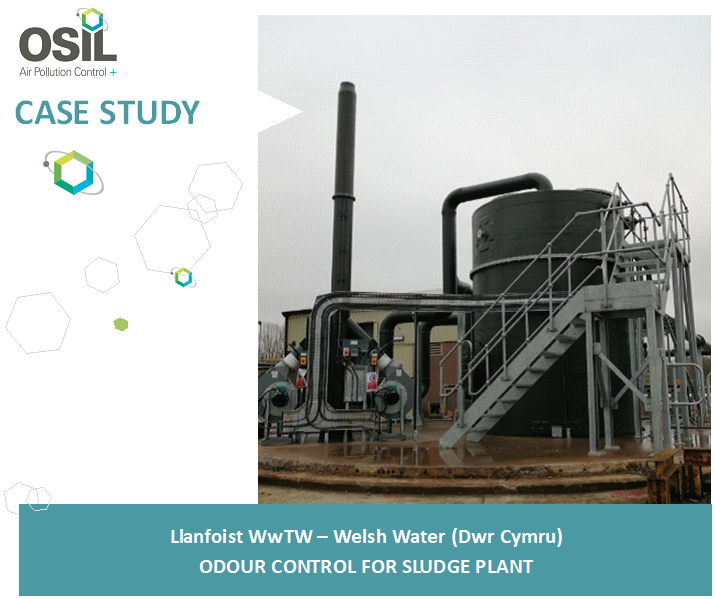

Read our Case Study on Welsh Water

Read how we installed an OCU at Llanfoist WwTW Sludge Plant.

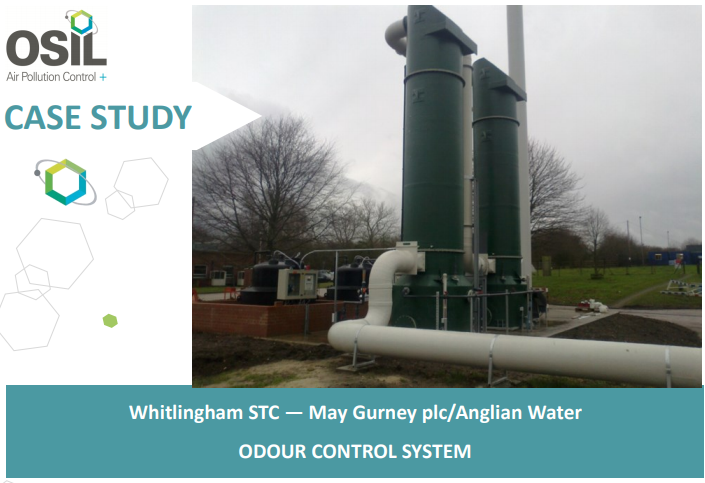

Read our Case Study: Anglian Water Services Limited

Read how we delivered our new OdaCompact System with 500ou/m³ performance guarantee from the stack at Whitlingham Sewage Treatment Works. OSIL delivered a robust solution that ensured an odour-free environment with low system footprint.

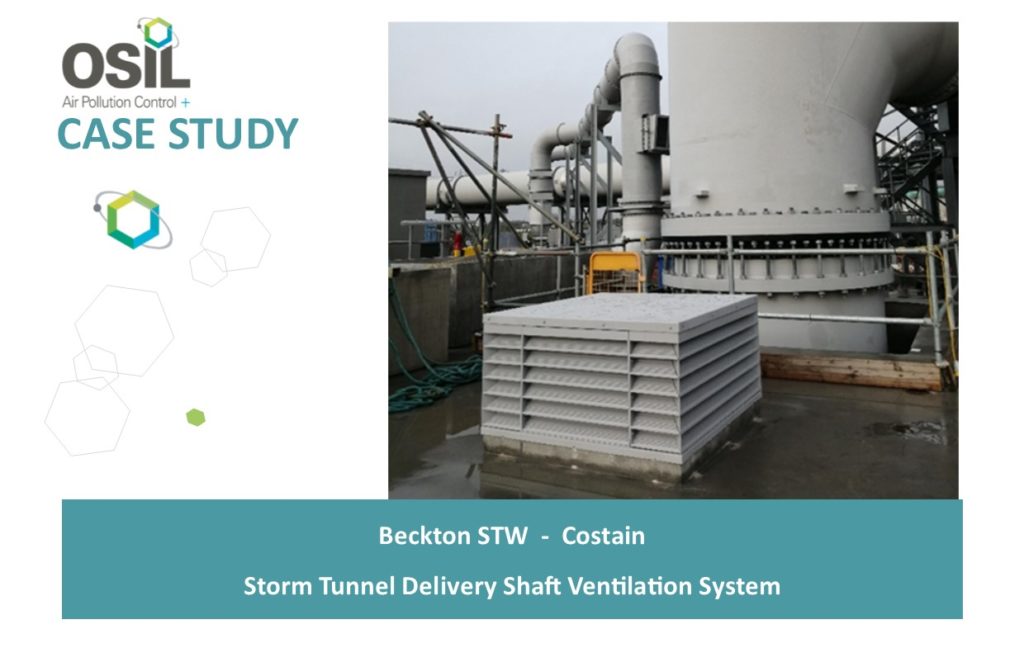

Read our Case Study on Beckton STW Costain

eight2O were contracted to provide Thames Tideway Tunnel (TTT) and Thames Water Utilities Ltd (TWUL) works that sit outside the main TTT contract at three standalone sites across London – Shad Thames PS; Beckton STW; and Bekesbourne Street.

The works at Beckton STW consisted of the construction of a Storm Tunnel with Delivery Shaft and Discharge Shaft along with associated mechanical and electrical works. To find out more, read our Case Study

Read our Case Study on Brancote STW – Severn Trent Water

Brancote Sewage Treatment Works was operating as a strategic sludge centre with one digester. However, after a sludge strategy alignment process assessment was carried out by Severn Trent Water this resulted in the re-classification of the Brancote site to a “rural works” changing its operations to a dewatering facility treating indigenous sludges and imports from the surrounding area. To find out more read our Case Study.

Read our Case Study on Banbury STW – Thames Water

Banbury Sewage Works had two existing odour control systems, The PFT System wasn’t operational and the existing Sludge Area System had deteriorated beyond effective treatment of odour on the site. To find out more ready our Case Study.

Read our Case Study on Tube Vents – United Utilities

New storm tanks have been installed in and around Oldham. Vents were needed to allow air to be drawn in when the storm tanks were been emptied and air to be pushed out when they fill up. When this air leaves the storm tank it could be odorous and this needed to be prevented from being released into the air where people are as this would be very unpleasant. To find our more read our Case Study.

Read our Case Study Mogden STW – Thames Water

Provide a system to remove odours produced by the newly constructed Surplus Activated Sludge Thickening System at Mogden Sewage Treatment Works. To find out more read our Case Study.

Read our Case Study on Mill Bay – South West Water

OSIL were commissioned to undertake the refurbishment of an existing Odour Control System at Mill Bay Pumping Station for South West Water situated in Plymouth following odour complaints from local residents. The original plan was to refurbish the existing odour control unit and replace the Carbon media. To find out more ready our Case Study.